Resistance Spot Welder, Projection Welder, Seam Welder, Flash Butt

Welders, Three Phase Welders and Capacitor Discharge Welders

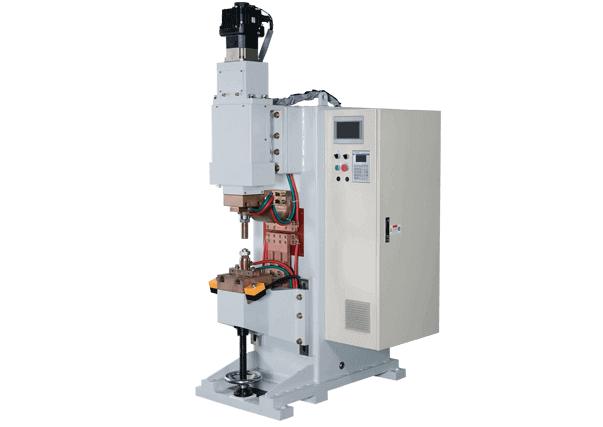

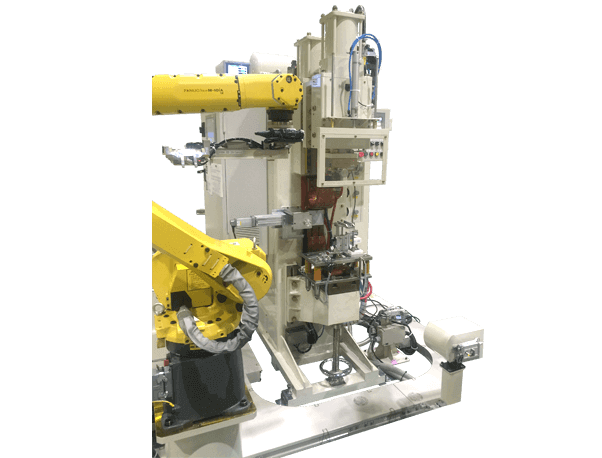

![]() Projection welding is characterized by joining the predetermined weld point or so called projections or embossments on the weld part with the parent material. Projection welding current and weld force are localized on the weld points unlike spot welding where the weld is determined by the size or shape of electrode. Projections for projection welding can be produced by embossing on sheet metal, machining or cold forging on a solid piece and press punch on the edge of a piece. Projection welding has wider applications than spot welding; from welding nuts and bolts to sheet components to as big as welding bearing bars and cross bars to form a grating panel. To know more about what a projection welding machine is and how it can be applied for, please check out this article.

Projection welding is characterized by joining the predetermined weld point or so called projections or embossments on the weld part with the parent material. Projection welding current and weld force are localized on the weld points unlike spot welding where the weld is determined by the size or shape of electrode. Projections for projection welding can be produced by embossing on sheet metal, machining or cold forging on a solid piece and press punch on the edge of a piece. Projection welding has wider applications than spot welding; from welding nuts and bolts to sheet components to as big as welding bearing bars and cross bars to form a grating panel. To know more about what a projection welding machine is and how it can be applied for, please check out this article.

How can we help?

If you have any business inquiries or product questions,

please feel free to contact us.